As a company that supports its clients primarily in the development of B2B solutions, it is particularly important for us to track down current trends and developments in the various industries and to anticipate them for our clients.

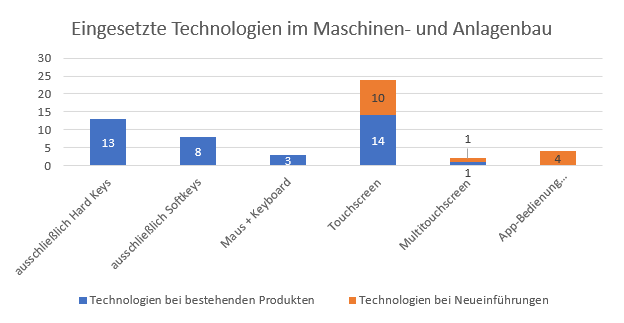

Of the existing machine and plant controls of the manufacturers considered, about the same number of companies used controls based on hardkeys (13) as on touchscreens (14). Fewer companies relied on the use of softkeys (8) or mouse and keyboard (3) for their solutions. One company had already implemented multitouch screens in the existing generation of systems. Not a single company had implemented a mobile operating concept or app operation in the existing machine and plant generation. Since all manufacturers sell different machines and systems within the company, it was possible that individual companies had solutions based exclusively on hard keys as well as solutions based exclusively on soft keys.

In addition to analyzing the current generation of devices, new launches were also specifically examined. A very uniform picture emerged:

All of the new solutions introduced in the period under review rely on the use of touchscreens, either as single (10) or multi-touchscreens (1). In addition, 4 of the manufacturers considered in this period have created a further operating option for their users in addition to introducing a new generation of devices. Thus, in the latest generation, these manufacturers enable remote operation via an app/mobile applications in addition to direct operation on the device.

Looking at the manufacturers on a company level, it can be seen that there is a big difference between innovative and less innovative companies. For example, 10 of the 11 companies (about 91%) using touchscreens in the new generation of devices are companies that already used devices with touchscreens in a previous generation. Only one additional manufacturer has made the switch from conventional operating methods (in this case exclusively hard keys) to touch. This also shows a difference in the way these companies approach their own clients: 11 of the 27 companies considered (approx. 41%) advertise that their solutions are easy to use. Of these 11 manufacturers, 9 are among the companies that use touchscreens. This includes the one company that has switched from hard keys to touchscreens. It can therefore be assumed that these companies see the ease of use of their solutions as a real added value for the client and place this prominently and specifically at the center of the benefits argumentation to the client.

Of the companies that do not use touch displays on their own machines and systems, only 2 cite the ease of operation of their own devices as a benefit for the client. In this group of companies, the simplicity of operation seems to play either a lesser role (e.g. due to a lower competitive situation) or a lower awareness of customer centricity.

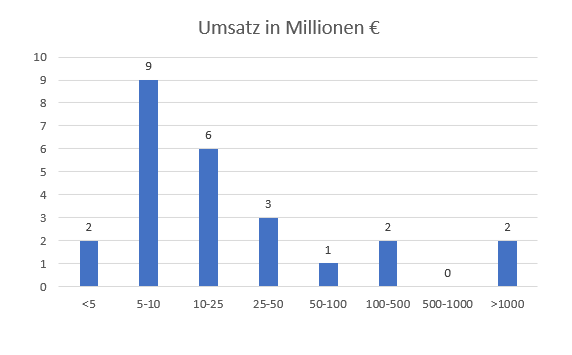

Looking at the size of the companies or their sales figures, it can be seen that most of the companies considered are in the range of 5-10 million euros in annual sales (last available annual financial statements). On average, the companies relying on more innovative technologies generated 255€ million in sales (including a billion-dollar company) or 59 million euros in sales excluding this company. This compares with average sales of €237 million for less innovative companies (also taking into account a billion-dollar company) or €11.3 million without this company. There is also a clear difference in the number of employees. For example, the innovative companies have an average of 1132 (or 307) employees, while the less innovative companies have 1272 (or 169) employees. Here, however, due to the limited observation, no statement can be made as to whether the high innovative strength leads to strong increases in sales and thus also employee growth, or whether the increased sales offer better opportunities for the development and use of innovative technologies.

In conclusion, however, it can be said that new technologies are increasingly finding their way into the more traditionally inclined mechanical and plant engineering sector as well, and that a rethink is taking place in the direction of customer centricity and simplicity. These arguments also often replace features as the primary selling points, so it can be assumed that better sales promotion could be achieved among companies here. The importance of good usability and innovative operation is increasingly finding its way into classic areas as well and presumably leads to competitive advantages for more innovative companies.